Some Diesel Engine Tips That Will Keep You Up and Running

[October 2013] Emergency generators are great to have, except when they do not generate during outages.

However, just starting and running the generator every so often might not tell you when a failure is impending. As Richard Rudman shows, some additional tests can be useful in improving successful generator operation.

I recently had an interesting learning experience with a diesel generator set that might be useful to BDR readers. The lesson started when the generator set did not. Start, that is….

Finding the Problem

At first it looked like a simple matter of a dead battery.

Unfortunately, a heavy-duty jumper battery did not improve the situation. Must either be a frozen engine or a bad starter, thought I.

I ruled out a frozen engine when, with the jumper battery in parallel with the generator set battery, there was rotation before the generator set’s automatic overcrank protection kicked in.

A DC Voltmeter across the battery showed a drop of 6 Volts from the unloaded 13.6 Volt parallel battery voltage during cranking. Aha! A bad starter motor.

You probably already guessed that your local auto parts stores do not stock replacement starter motors for multi-kilowatt three-phase generator set diesel engines, nor did the local support point for the engine. It took the local support people a day to get a replacement.

And that started me thinking.

Improving the Maintenance Plan

Might there be a way to predict that a starter motor might be heading south before it arrives there?

There are some lessons that I took out of this experience, so let me share them.

First of all, whenever you do routine engine maintenance checks, record the voltage drop across the battery while the engine is cranking before it starts. Assume that first reading you take is a baseline for future reference.

Knowing a 6 Volt drop had occurred when I measured the bad starter motor, I measured with the new starter motor. This time, there was only a 2 Volt drop while cranking. A drop of more than 2 Volts on this engine will now tell me something bad may be about to happen – and one hopes the problem can be caught before the generator is needed for emergency power restoration.

At this point, I considered the question of what other tests there were that I could do myself, short of bringing in a generator company technician to do a full set of load tests?

Roll Your Own Generator Tests

Before going any further, it is important that you read the following and understand it:

WARNING! The tests described below can be dangerous to you and your equipment! If you are not trained to safely work around high amperage DC, toxic chemicals, and rotating machinery and other engine hazards, work with some-one who has been trained, so you can learn how to do the tests.

Furthermore, while you will be dealing with low level DC, battery currents are perfectly capable of causing sparks, burns, and more.

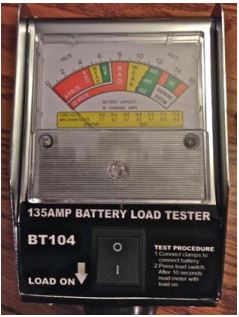

The first thing you can do is to find a good local auto parts store and buy a Super Start Professional Battery Tester.

The Model BT104 is Part # 44200 at O’Reilly Auto Parts. It should cost a bit less than $50.

This battery load tester will draw a lot of Amps

This is a meter with an internal 0.1 Ohm dummy load that can draw 135 Amps for a short battery stress test.

When you begin using this tester, please be careful! The caution label on the heat sink says:

WARNING

VERY HOT SURFACE.

Folks, they are not kidding.

The recommended ten-second test will cause the internal resistor to glow cherry-red.

Contact with the heat sink will cause a serious burn that would probably make a flat iron on “high” look like an ice cube tray in comparison.

So, be very careful when (and where) you put the tester down after you are through, and, if possible, use the handy metal hook that comes with the tester to hang it safely in mid-air.

You may also wish to use the Super Start tester for your periodic, in-service battery health check. With its cables across the battery, crank the engine and observe the actual voltage drop as the generator set starts.

Replace All Old Batteries

Remember, we are talking about a generator you want to depend upon in emergency situations.

That is why it is important to routinely replace all engine batteries that are more than four years old. If possible:

- Get rid of all old batteries that need to have water added manually.

- Avoid deep cycle marine batteries.

- Go to a truck parts store and buy a heavy-duty part that will start a big rig.

The more cold cranking Amps you can safely fit in the generator housing, the better.

Old Style Batteries

If you have old style batteries that are not the newer, sealed, no maintenance types, check the specific gravity of the acid electrolyte with a hydrometer during each maintenance period.

O’Reilly Auto Parts has a nifty little bulb hydrometer for under $2.00. Because there is acid involved, you should always take standard precautions when dealing with chemicals, such as wearing eye protection at all times.

This time it turned out that, in addition to the starter motor issue, my generator set’s battery had a dead cell. As any experienced engineer knows, troubles often happen in pairs, trios, quartets, and small mobs.

Check and Double Check

During your maintenance inspection of the generator, take schedule the time to clean and check all battery cables and terminals.

Here is why that is important: On one of my generators, I found that someone during the station’s past history did not install the proper post terminals when the battery was changed.

Over time, the nut holding the negative post was almost rounded off. The terminals and nuts were quickly replaced.

A good maintenance tip: having some common parts on hand – where you can use install them right away – including some of those anti-corrosion disks, will go a long way to reducing contact and deterioration issues.

Obviously, it is always best to be able to do any work needed on a generator well before any bad weather or other emergency issues arise. Working on it during a storm or in the middle of the night darkness just is not as much fun.

On the other hand, when you have a well-planned maintenance program and do as much as possible to know the condition of your generator and prepare for as many contingencies as possible, you will be much more comfortable.

Instead of panic, anxiety, or working in adverse conditions, you will know that your generator is running happily and you can confidently hum along with the program on-air.

– – –

A broadcast engineer with extensive experience from small to major markets, Richard Rudman is a regular contributor to the BDR and is the owner of Remote Possibilities in Santa Paula, CA. Contact him at rar01@mac.com