Keeping Your AM Well-Grounded

[February 2014] It startles people to learn that half of an AM antenna is invisible, hidden under the dirt, grass, parking lots, etc., that surround radio towers.

We know towers need periodically to be inspected and maintained with fresh paint and guy wire retensioning. Ground system also needs regular attention. Kevin Kidd offers some tips to keep your signal strength at its peak.

Misconceptions about AM ground systems are common.

Largely because they are rarely seen, they tend to be forgotten as regards regular maintenance. But make no mistake about it, ground systems need maintenance.

Over my 17 years or so of building and maintaining them, I have seen some well-kept sites and some that appear to have been abandoned for years. I also have seen sites where the station booms out over the area and sites where thieves have cut out part or all of the ground system, crippling the station’s signal.

See It As A System

I really enjoy working with what you might call the “hidden half of our antenna systems.”

These years of experience have given me a lot of knowledge and insight into what makes them work well – and how to keep them that way. Even better, as a ham operator I even get to roll my work into my hobby

On the other hand, most folks have never really seen a ground system unless they were on site when it was installed, or have seen it exposed by erosion. That makes it hard for them to fully understand it, or sometimes even to know what questions to ask about it.

A good place to start is to review the system as a whole, then consider each of its parts in a logical, methodical way. Although a large part of the ground system is copper – and its electrical properties – the key to understanding it is in how that copper is designed, laid out, and connected so as to provide an efficient ground plane for the antenna sections above ground.

A Mechanical Approach

In most cases, a properly constructed ground system in decent soil can be expected to last around thirty years or so.

In some cases, if the soil and its pH are kind to the copper and the brazing alloys, the ground system may last for many years longer. Unfortunately, some soils are very destructive to copper and brazing alloys, often causing a ground system to fail well sort of the benchmark.

The actual lifespan of any antenna system depends on several factors: the composition of the soil, whether or not the overall ground infrastructure was well installed, and a program of regular maintenance.

To demonstrate what can happen, look at this failed guy anchor.

It was only after a relatively few years of service that this anchor came apart, taking down two towers when it failed.

Poor workmanship and/or materials selection (for example, brazing alloy that has low or no silver content in the solder) are among the reasons for the more common failures observed.

Such failures can happen in an amazingly short time – occasionally it can happen within months after installation.

As you look at the physics of a ground system with the eye of experience, it is easy to see where and how most problems occur – and how best to solve them.

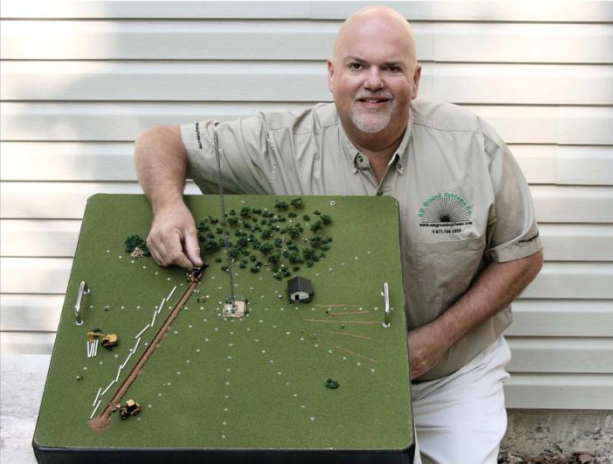

My scale model shows the parts of a ground system and some of the potential problems.

Indeed, when something happens to older ground systems it is usually something purely mechanical: The wrong brazing alloy was used, or someone did not know (or care) that the ground system must be connected to something else to be effective. At newer sites, the majority of problems are almost always related to one or another of that old couple: Old Father Time or Mother Nature.

Inspection Time

So, what are the things a good ground system crew will look for during an inspection? Mainly the same things you should look for during your own inspections.

The first – and most obvious thing to look for – is to see if there is visible damage.

Are pieces of copper wire sticking up, out of the ground? Whether from erosion or theft, there usually is evidence of these kinds of damage somewhere on the site. A good check, if you have access to a field intensity meter, is to go out to the edge of the field and see if you can detect each radial on the meter.

Following that, the next step is to see if the connections between the wires and straps are still intact and solid. Keep in mind that major issues can be caused by small problems – a single missing or broken connection at the right (wrong) place can render an entire ground system effectively useless.

Check the ground system connections to the Antenna Tuning Unit(s), any ground straps, rods, or stakes, as well as the fence(s) around the tower(s) and the tower field itself. While not strictly the ground system itself, check the guy anchors for evidence of metal deterioration.

Preventing Problems

At most sites, grass, shrubs, even trees will grow in the tower field. These need to be controlled.

Left alone over time, they will start to stretch (and break) the installed copper ground system or damage guy wires – they can even short out the transmission system if they grow back too big inside the tower fence.

Mowing is good. Careful application of chemicals to reduce growth is also good. Blading the ground definitely is not good.

Another area to consider is site secuity, since there is a large investment of money in the ground at an AM station: The ongoing rash of copper thefts, driven by higher prices for scrap metals, has created a costly, inconvenient problem for many stations.

Clearly you want to know immediately if this becomes a problem. The solution is one of site security, a topic for another time.

Ensure a Good Ground System

Maintaining a ground system and protecting it from vandals is not a trivial matter. However, by giving regular attention to your ground system you will reduce the scale and cost of any repairs needed and prevent many problems before they can get started.

– – –

Kevin C. Kidd, CSRE/AMD is the proprietor of AM Ground Systems Company and KK Broadcast Engineering. More information can be obtained by calling 1-877-766-2999 or visiting www.amgroundsystems.com