A Maintenance Program That Works!

[February 2022] There are many things that a broadcast engineer needs to keep in mind so as to keep a station on the air and operating without problems. While we do not go “looking to find trouble” it turns out that if you do not look for it, trouble will find you!

Whether you have been working at a station for decades or have just accepted a job at a new station, putting a good maintenance plan into action has substantial benefits.

And it all starts with documentation!

Sometimes we are so busy, racing from fire to fire, it seems impossible to find time to write everything down. For those who have been on the job a while, having notes to remind you about station operations can save a lot of time doing the same troubleshooting over and over – plus it is the right thing to have on file for the next man.

Some years ago, I was called in to care for a station. As I checked the documentation at the transmitter site, I was pleased to see logs, notes, and manuals set up by myself – 30 years earlier. Combined with more recent notes, it was relatively easy to know what was and what was not operating “normally.”

So, you can see that for the stand-in or the “new guy,” proper documentation not only provides clues to any existing issues but provides a baseline for “normal” operations.

THE STATION LOG

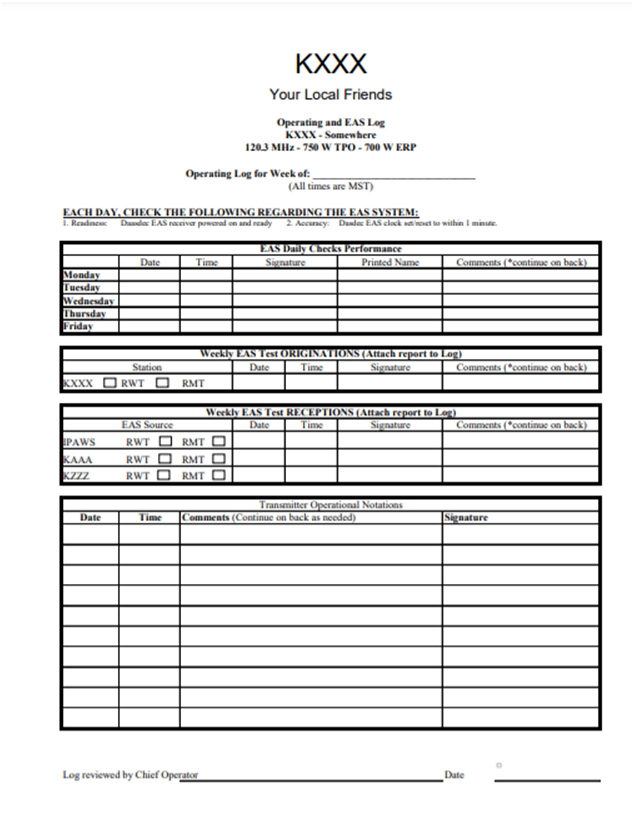

One of the two key documents that should be properly cared for is the Station Log.

According to the FCC, at 73.1800, the Station Log (or Operating Log) is to be kept by competent employees with actual knowledge of the facts. Entries are to be orderly and legible, signed with the local time and date by the person entering the data. Multiple pages are to be numbered.

Section 73.1820 lists six main items required to be in the Station Log;

- Daily check for proper operation of tower lighting, along with records of what was done in case of extinguishment or improper operation, and notation when repairs or replacements are accomplished. (Section 17.47).

- Entry of the weekly EAS tests and activations under Part 11 of the FCC Rules. Such data may be in a special EAS log (including via a digital log in the EAS receiver or on diskette or flash drive) but is still part of the Station Log. A daily check of the EAS receiver operation may be desirable.

- Data resulting from Directional AM station operations without an FCC-approved sampling system. This is largely no longer relevant for the vast majority of AM stations.

- Notation of any operation outside the limits of the station authorization.

- Notation of when transmission is terminated and when it is restored.

- Any other entry required by a station’s authorization or FCC actions.

There is one more aspect to the Station Log: it is to be reviewed each week by the Chief Operator (CO) (whose letter of appointment is signed by station management, and available to inspectors) to ensure all entries are done correctly, verifying the station is operating as required. Before signing and dating the log, the CO will initiate any corrective actions necessary and notify the station licensee of any repetitive issues.

Here is one example of a Station Log,

By the way, there is nothing to say you cannot do an entire month on one sheet of paper. Some stations save the month’s EAS or other items in computer file, with a cover that shows weekly compliance.

Also, you may notice that logging transmitter readings, as in past years, is no longer required. However, stations should make a practice of periodically logging operating parameters in case an FCC Agent comes. This information can be in the Station Log or in a separate (paper or digital) file. In case of some issue, such data can be used to prove the station normally was operating correctly.

Station logs are to be kept for two years, unless the FCC asks for them or by prudent action to ensure records of operations subject to a complaint or other problems are saved as long as necessary.

MAINTENANCE LOG

In years past, stations would keep a Maintenance Log to detail all work at the transmitter site.

More recently, smart engineers will indeed have something called an Activity Log, Maintenance Activity, Station Notes, Technical Notebook, Repair Log, Maintenance Log, or something else – you get the idea. This is not necessarily an “official log” subject to inspection by non-employees, unless it is so desired.

Primarily, this log is for station personnel to note and find material that defines the station’s normal operation and any repairs or adjustments made to ensure such operation. As we said at the start, this often is extremely helpful to spark memories of past work or to help a new staffer to understand the key aspects of the station’s life.

THINGS TO RECORD

Among the items that might be placed in such a maintenance log might be notations of:

- An extended set of observed operating parameters, and a comparison to the transmitter test data sheet.

- Any variance from normal parameters and what, if anything, was done to correct things.

- Regular generator testing (especially under load) and maintenance. (In some areas, generator activity needs to be a separate log, for governmental agencies.) While thinking of power, do not forget to check the UPS – perhaps noting, when available, the percentage of battery available.

- Regular site inspections of

- air filters

- transmitter temperatures

- tower lights and tower lighting controls and sample systems

- tower structural integrity

- condition of site – fencing, gates, locks, warning signs

- condition of site – not overgrown or covered with refuse

- condition of site – watching for intruders, vandalism, or used shells

- HVAC – ensuring both units work

- building integrity

- absence of insects and other fauna

- the security cameras and/or any other general security matters.

OTHER ASPECTS OF DOCUMENTATION

In terms of looking for problems before they become critical, there are some other thing that should be part of an inspection visit. These are documents you want to make sure are always available.

For example you do not want to wait for an off-air emergency to do a routine check to ensure

- the full “library” of manuals are available either in paper or via Internet.

- a full page – or more – of names and phone numbers of manufacturers to call when needed. (Knowing whom to call and where can often save you hours of troubleshooting and swapping different replacement parts and circuit boards.)

- account and serial numbers (or, in the case of power companies, the meter or pole number) for each piece of gear in the building. In some cases you may be required to provide a user name, password, phone number associated with the account, etc. Having this on hand will save a lot of time and frustration.

- a list of important replacement parts. Include most all things like ICs, capacitors, batteries, etc., so that you can easily recorder the parts you use.

- spares should be clearly marked for their use if for a specific piece of gear. (Which power supply fits which piece of gear should not be “trial and error.”)

- periodically check to ensure all tools are still on site and have not been “borrowed” and lost. This should include knowing a complete First Aid kit is on site.

- other items that you should not have to wonder if they are available are convenience items like a decent chair/stool, fresh water and snacks, just in case you find yourself either working or stuck there for some time.

NOW, JUST WHERE IS IT?

Have you ever looked for a replacement part, only to find it missing, and you do not know where it went?

Good documentation as part of a maintenance program will include a “loaner” sheet, where items are noted. Have you helped out a fellow engineer? Mark it down. And, some advocate making sure that address labels should be on anything that is loaned out to help another station. It might take a while, but you might have to identify an item to a replacement engineer – and prove it is yours.

If you drag something from the studio to the transmitter – or visa versa – a notation will help remind you where to restore it when finished.

DOCUMENT, DOCUMENT, DOCUMENT!

To conclude this discussion on maintenance, let us take a moment to repeat the key point: document things! It actually is easier today than ever to use a form of documentation that is relatively new but can add a lot of important information.

You probably have it with you right now: images from your smartphone.

As you do your site inspection, take a lot of pictures, and even a few videos. As appropriate, they can be printed out and included as part of the maintenance logs. A snapshot of the transmitter AUI will be easy to read. And no one can say they cannot read your writing – even you!

When making repairs or replacement, you might even use the pictures/videos as you take something apart, so you remember where everything goes when putting it back together – especially what looks like leftover parts!

Finally, depending upon the situation, you might find it to be a good idea to develop a “photo album” of the site and each piece of gear, with notations on where it is in the signal flow and what is needed to keep it going. Even if you do not need it, the next guy in will thank you for your attention to detail.

What else works for you? Let us know so we can share the knowledge! – BDR

– – –

It only takes 30 seconds to sign up here for the one-time-a-week BDR Newsletter.