Inspecting a Tower – Going on Up

[January 2013] Regular inspections and maintenance can go a long way to preventing awkward silence on the dial.

What should be on the inspection list, and what should be outsourced to a professional tower crew to inspect? Curt “Cowboy” Flick has years of experience in climbing, inspecting, and repairing towers and antennas. His account of what he looks for will help you evaluate the inspections done on your tower(s).

To do a complete tower inspection, whether AM or FM, eventually someone has to get on the tower and climb up.

Some towers are on top of buildings, others may have elevators, but eventually, it is time to bring out the harness and stand on the metal.

But first, an important step: One of the very first things we need to assess is whether the tower can hold a man!

Before Taking the First Step

While this might seem obvious to some, trust me: I have seen towers that likely would not handle the extra weight of even one man.

A careful check while on the ground – and as a climb starts is essential. Heavy flaking rust, holes, and hollow members are all bad signs. Over the years, we have seen cases where the hollow member towers rust from inside. While they may look great on the outside, at times a climber’s foot will step right through a horizontal cross member. Not good at all.

Should that occur at your site, expect the inspection to be immediately terminated with a recommendation the tower be dropped as soon as possible – lest it drop itself on its own schedule. Being a careful climber myself, I am confident in saying that if it appears the structure is so badly neglected that it may not hold my scrawny little self, it is a safe bet no one else will climb it either.

Going Aloft, Beginning a Climb

Assuming the tower is in decent condition, permitting a climb, a good climber will prepare his safety harness and checklist before beginning his ascension.

On the way up, he will want to check the paint and anything that can be seen under the paint.

Part of the process is physically checking each component. During the inspection, the paint should not brush off with a simple hand wipe.

In addition to the condition of the paint, we need to ensure the paint matches the correct colors on the FAA approved color chart all the way to the top (the paint condition almost always gets worse the higher one goes).

Nuts and Bolts

I always keep an eye out for missing bolts. You might be surprised! There are a lot of nuts and bolts on a tower, subject to temperature changes, rain, snow, ice, wind, and other stresses. Hardware loss has dropped many a tower.

Obviously, the nuts and bolts should be tight, installed with the nuts on top. That way a nut coming loose will cause the bolt to fall out, becoming more obvious. If they were installed with the nut on the bottom, we will need to take more time (a lot more time) and check that there is a nut on each and every bolt.

Also, nuts and bolts should be painted over to protect them from the elements.

If the paint is flaking at all, we will uncover a few nuts to check their integrity. Cracks in the paint can be a sign of rust underneath, or may simply be a sign of bad paint.

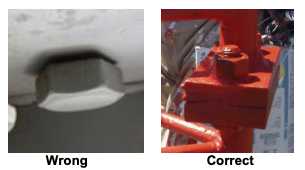

One place that should not have paint is a weep hole. These should be at the bottom of each section and clear, so any moisture can dry out – and not rot the tower out from the inside.

Guy Wire Inspection

Since rust is generally worse aloft, the condition of the guy wires at ground level may not tell the whole story. Thus, a careful inspection should be done at the points where the guy wires anchor to the tower. Since guy wires do move with wind, there can be some wear at these points, especially on an old tower, though it is seldom bad enough to be of concern.

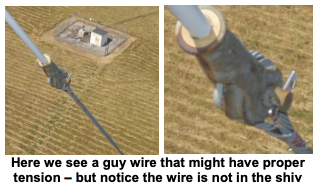

As we pass each guy level, we will look closely at the condition of the guy wires aloft, as far out as we can reasonably see. We want to check, on an AM stick, the insulators, preforms, or cable clamps, as best we can.

While this tower may have been standing for a while, it is problems like this that can give way enough during a storm to cause total failure.

More Than Just the Tower

Anything tied to the tower, such as conduits and transmission lines will need to have the security of their mounting checked.

If there are one or more runs of coax on the tower, we will look closely at them to assess their 3 condition. Has the outer covering been scuffed or rubbed through at any point? Are they secure enough to stand the wind without excessive movement? We will want to look closely at the tie points, to make sure that wind movement has not caused anything to be of concern at these wear prone points.

Furthermore, we look at hard lines for evidence of previous repairs, and to check that they are still serviceable. We look for any scrubbing of the outer surface that might indicate a future problem in the making. Are the lines properly supported? The condition of any jumpers, ground kits, and weatherproofing of all of them needs to be checked carefully.

Missing nylon buttons inside the hangers on hard line coax will eventually wear through the outer conductor and cause an unscheduled burn out. Missing springs cause the weight of the line to lose proper support over its full length – and transfer excess load to the top rigid hanger.

By the way, tie wraps do not fare well in sunlight. I have seen conduits come loose and begin flapping in the breeze with a simple finger pull on a sun-exposed tie wrap. Something more substantial would be in order, and should be installed as soon as a deteriorated tie wrap is found.

Coax “snap in” hangers generally hold up pretty good, if they were installed correctly. Still, they should be checked out. Joints especially, but the overall condition of any Electro-Mechanical Tubing (EMT) conduits are subject to rust.

Other Attachments

STL or any other antenna mounted to the tower should be checked for the condition and security of the mounts – that they are not loose, excessively rusted, and are in generally good condition.

The lightning rod or rods at the top need to be checked out. Also the static dissipaters that are found on many towers. Since they move quite a bit in the wind, they are prime candidates for coming loose.

The Lighting System

Light wiring deteriorates with time, so any exposed SO (oil resistant Service Cord) jumpers should be flexed to see if they crack and need attention. Light lenses should be checked for cracks and small caliber bullet holes, as well as build up of environmental dirt.

Where there is evidence of lightning damage, replacement needs to be made. In fact, if you know in advance that there is damage – perhaps you can see white light due to a damaged lens – you can alert the climber and have it replaced during the inspection.

Indeed, many stations take the opportunity presented by an inspection to change out the beacons at the same time, Look at it this way: it is cheap insurance; the cost of the bulbs is minor compared to needing an emergency climb to replace a beacon.

Taking the Larger View

While aloft, it is smart to take a look back down toward the ground.

A “bird’s eye view” will sometimes expose things in the field, or at the anchors, that just will not be seen from the ground – or are just too easy to miss while on the ground. For example, from the top, it is pretty easy to see if a tower is kinked, twisted, or otherwise out of plumb.

Especially from this vantage point, but actually at any place on the tower, a digital camera or camera phone can prove to be a great asset. If we find something we think needs immediate attention, we can send a photo to you on the ground right now and make arrangements to take care of the problem, at least temporarily.

Your Tower and Your Future

You should insist on a written report from your tower inspector. As we just noted, pictures are good – the more the better.

Now, do not just file the report. Read it. Think about it. Remember, even if the inspector and his crew say you need to do something, you should know why and see the evidence, just like you would if the car mechanic shows you a leaky hose.

On the other hand, if the crew does not recommend any immediate repairs, it is your station that will be off the air if they are wrong.

In general, it is all about that most uncommon of things, common sense. Do you want this tower to stand for another year, or another 20 years, or are you looking for the least costly thing that can be done now?

Tell your climber what aspects or areas where you want him or her to pay special attention – and why.

Perhaps you anticipate no problems – it is just a routine “to be sure” inspection. Still, tell your climber the long term plan. If it just is “get by cheap,” that is one thing. If it is planning next year’s budget, that is something else again. If it is knowing that there will be no worries for the next decade, that is yet quite another.

Regardless, arranging for regular inspections by an experienced climber will help prevent premature failure, especially when confronted by extreme weather or other stresses.

– – –

Curt “Cowboy” Flick is a broadcast engineer based in Akron, OH. He is experienced in areas from computers and studio inputs to tower climbing and maintenance. You can contact him at curt@spam-o-matic.com