Electrical Safety in the Transmitter Shack

[May 2013] Safety is, as it has been said: “Job One.” Yet, broadcast engineers are often under pressure to diagnose and quickly repair a transmitter, so the station can get back on the air at full power. As Richard Garrett explains, it is wise to remember and recognize safety issues.

Many hazards exist in a transmitter shack, with electrical hazards being among the most prevalent. Such hazards include electrical shock, electrical explosion, and electrical burns. In fact, electrical shock experiences are not uncommon among engineers and technicians.

Electrical shock – the effect of current through the body – can cause severe pain, loss of muscle control, internal bleeding, and internal organ damage as well as cardiac arrest.

Learning how to better protect oneself and one’s colleagues is very important.

First: Be Aware

Although it sounds counter-intuitive at first, a large number of fatal shocks occur among those who know better – including broadcast engineers, the very people who should know best when and how to protect themselves.

But, even more as surprising, you do not need to connect with the high voltage transformer of a transmitter to be in danger of a fatal accident. Actually, severity of a shock is dependent on the amount of current flow through the body, the path of current flow, and the length of time of current flow. As it turns out, 75 Volts can be just as lethal as 750 Volts.

It Does Not Take Much Current

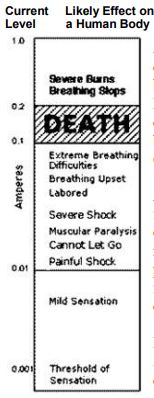

According to charts from various agencies and electrical industry sources, as little as 50 mA can cause death if its path goes through the human heart.

Just consider how little current it takes to affect a person. The current levels on the accompanying chart on the next page should grab your attention.

At the lowest level, a person can feel a current of at least 1 mA (rms) of AC at 60 Hz. It manifests itself as a slight tingle.

At 5 mA, a slight shock can be felt, although probably not very painful. Depending upon the individual, the shock will become painful between 6 and 16 mA.

As the current advances from 17 mA to 99 mA, extreme pain occurs and muscular paralysis will prevent the individual from letting go of the circuit.

In the range above about 50 mA, death becomes quite possible.

At currents between 100 mA to 2000 mA, ventricular fibrillation is caused; death is likely. And once you past 2000 mA, cardiac arrest and severe burns almost certainly will prove fatal.

It Does Not Take Much

To put some of this in perspective, not too long ago, a major manufacturer of consumer goods was forced to issue a safety recall due to danger from a 7-Watt nightlight.

If you do the math, at 120 Volts, 7 Watts will draw around 60 mA – enough to kill.

Understand the Work Place

Many broadcast engineers find themselves having to work with or around energized parts when taking voltage and current measurements, operating disconnect and circuit breakers, removing panels, and opening doors for inspection.

Clearly, it is never recommended that someone work on live circuits. Yet, during the course of diagnosing a problem or repairing a transmitter, sometimes it is necessary to have it operating. This puts the person at a high risk of shock from touching energized parts.

It is all too easy to set aside safe work practices in an effort to speed repairs, especially with any added pressure of a transmitter being off the air.

That is why persons who work on energized circuits should take time to assess all risks, devise a work plan, and discuss it with their safety buddy prior to beginning work.

Procedures That Save Lives

Indeed, to create a safe work environment, all station personnel involved should be familiar with the equipment itself, as well the proper techniques to use around such energized equipment, and any needed protective gear.

Proper protective equipment includes insulated tools, insulated fuse holding tools, fiberglass ladders, and rubber insulating equipment, along with personal protective equipment (PPE) such as safety glasses, protective head gear and clothing, and similar items as required for the task.

Persons who do not know nor understand the potential hazards should not try to work on any station equipment. The sales manager or computer wizard who only thinks he knows what he is doing can be dangerous to his own health as well as that of others.

A Useful Checklist

You are encouraged to implement the following procedures at your transmitter shack. They will help reduce or eliminate exposure to electrical hazards, creating a safer work environment.

- If you are tired, go home. A delay in repair is much better than a fatal mistake.

- Whenever possible work only on de-energized equipment.

- Verify the system is de-energized by operating the controls and use test equipment to insure hazards are not present.

- Even when you turn the power off, never work on electrical or electronic equipment unless there is another person present who is familiar with the operation and hazards of the equipment. Always take time to warn them about the dangerous areas.

- Make sure to remove metallic objects like rings, watches, neck-laces, earrings, or other similar items prior to working on electrical equipment.

- Observe the “One-Hand Rule.” Keep one hand in a pocket and greatly reduce the chance of a shock across the heart.

- Use the shorting stick – every time! Stored energy in capacitors and other such items must be discharged prior to beginning work. All it takes is one bleeder resistor to open up and an unexpected shock can occur.

Proper use of the shorting stick can prevent unwanted surprises

- Prior to use, check all test equipment for worn or damaged areas that may pose a hazard to the operator. Do not forget items such an extension cords that may have broken, damaged wires, or missing ground prongs.

- Avoid working on equipment when you, your tools, or clothing are wet. Clean up any spills promptly and keep floors dry.

- Stop work when thunder storms and lightning are in the area.

- Never remove panels or defeat interlocks.

- Do use the lockout/tagout methods to prevent unexpected startup.

If you lock out a breaker, it is much less likely

An unaware co-worker will try to turn it on.

- Place a lock and tag on each device needed to disconnect power to the equipment.

- If a lock cannot be used then isolate the circuit by removing a fuse, block a controlling switch or open another controlling switch.

Before Re-Energizing Equipment

- Perform a visual inspection to insure that all tools, test equipment, jumpers and other devices have been removed.

- Install panels and covers.

- Warn others to stay clear of equipment.

- Visually check that all others are clear of all hazards.

- The lock and tag should be removed only by the person that installed it on the locked out device.

- Then, carefully energize.

Training is Good

There are other things that can and should be a part of proper preparation when working on potentially lethal equipment.

Station policy should require any person working – or with someone working – on electrical equipment to be trained in CPR principles. CPR classes will teach important information and needed techniques in case of an emergency.

For example, if someone does receive a shock, they should be taken to a hospital as quickly as possible – even if they “appear to be ok” – and checked for any damage to the heart muscles or any other part of the body.

Learning about CPR and how to administer it can be easily the difference between life and death. Long before outside help can arrive, an electrical shock accident victim could die, especially if you are in an isolated place, far from safety services.

Check into the CPR classes offered locally. Making it a station policy will help you keep up with the latest information on how to apply the techniques in case of accident.

Bottom line: it is cheap insurance for the station to support, or even pay for these classes.

Another good policy is to ensure regular communication between the technicians and someone back at the studio, or elsewhere. A regular phone call or intercom interaction is a good way to keep everyone awake, aware of their surroundings – and alive.

Broadcasters who keep in mind the potential hazards on site, as well as safe engineering practices, will enjoy a safer – and longer – life.

– – –

Richard Garrett is the Field Service Manager for Continental Electronics Corporation in Dallas, TX. You can contact Richard at: rgarrett@contelec.com