Avoiding the Pink Tower Syndrome

[May 2011] The warmth of summer is just around the corner and many of you have a long list of projects in your back pocket. For most, sooner or later tower maintenance works its way to the top of the list. And part of the maintenance is making sure the tower can be seen. Ed Trombley explains.

With the FCC Enforcement Bureau paying so much more attention to tower site issues, it will save you a lot of hassle – and fines – if you are proactive in ensuring the tower fence is in good repair, the lights work properly, and the tower paint covers the metal – with the right colors.

The Right Color

Did you know that there is a Federal Standard for tower paint? Pink is my favorite crayon, but it is the wrong color for a broadcast tower.

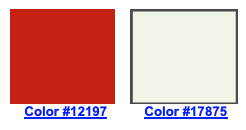

FAA Advisory Circular AC 70/7460-1K – that same document that tells us where the lights need to be placed on our towers, also gives some hints on tower paint. The correct colors are identified in the AC 70/7460-1K Circular in paragraph 121 as #12197 and #17875, or International Orange and White. Some may use a name like Aviation Orange or Tower White, but the key is that it should meet the FAA specifications.

In order to understand exactly what a contractor is offering, you should know that there are two basic kinds of paint that meet the FAA specifications: Exterior Acrylic Waterborne Paint and Exterior Solvent borne Alkyd Based Paint. They come under various trade names from different companies, it best to use a major brand recommended by more than one contractor.

According to the FAA, “Approved colors shall be formulated without the use of Lead, Zinc Chromate or other heavy metals …,” and meet Federal EPA regulations. More information is in the FAA Circular document AC 70/7460-1K (Chapter 12/Page 33).

Knowing this is important for two reasons. First, the color needs to match the “standard” chart to be legal, and second, some unscrupulous companies will use watered down paint which might “look” right as it is applied, but will fade soon after.

Not a Place to Save Money

Some of you have discovered the difference between cheap paint and the real stuff the hard way.

Tower paint that meets the federal standard is expensive, last year it was approaching $200.00 for a 5-gallon pail (up almost 200% in 7 years). So make sure you get what you paid for. Although most engineers start out concerned with the color of the paint, you should also be concerned with how long it will last. There are some stories out there that Allis-Chalmers tractor orange is a close match and that may be true but enamel tractor paint is not the answer.

Over the last several years a few broadcast towers that I know of were re-painted using bootleg latex paint that faded to a non-compliant color many years too early. It looked good in the bucket but it just did not have any resistance to ultra-violet light and weather. So three years later, the State Alternative Broadcast Inspection Program (ABIP) compliance guy is on site holding up his FAA In-Service Orange Color Tolerance Chart, wondering what happened. ABIP Inspector Ken Benner eyeballs tower paint

Over the last several years a few broadcast towers that I know of were re-painted using bootleg latex paint that faded to a non-compliant color many years too early. It looked good in the bucket but it just did not have any resistance to ultra-violet light and weather. So three years later, the State Alternative Broadcast Inspection Program (ABIP) compliance guy is on site holding up his FAA In-Service Orange Color Tolerance Chart, wondering what happened. ABIP Inspector Ken Benner eyeballs tower paint

Several hours later, you are explaining to the boss that the great deal you got on the last tower paint job was not all that good. Your results may vary.

Evaluating the Bids

Bids and quotes for tower painting can vary greatly depending on the work load of the tower crew, cost of the paint, and the starting condition of your tower.

If you have cared for your tower in the past, it may not need much prep work before the paint goes on. If you have inherited the Titanic of towers, like an old Windcharger or some other erector set special, your estimator may charge you a nuisance fee to even consider the job. Towers made from flat or angle steel members have higher wind loads and they also require more paint to cover that wind load area.

As you assemble your three bids, the cost and/or quality of the paint may become an issue. When employing a crew to re-paint your tower, please make sure your contract with them specifies paint that meets FAA AC 70/7460-1K as stated in paragraph 121, and FED-STD-595, and further specifies the proper number and width of the bands of orange and white – with orange at the top and bottom!

Watch the Paint Crew

Anytime there are contractors on site, there needs to be a station employee on site, for several reasons.

Tower paint crews are not made up seasoned tower riggers. Just for safety, somebody has to be observing the project. Furthermore, I have seen side marker lights, guy insulators, antenna bays, photo cell windows and a few cars that have ended up displaying renegade paint. There is even a four tower array that I know of, that has five bands of alternating orange and white paint. (They got the towers painted by a guy who paints water towers. He sure enough gave them one super duper steal of a deal.)

Among the other things to check is to make sure every bucket has a label stating the paint meets the FAA/GOV standard for color, wear and weather. You can always contact a known tower company that builds towers and buy the paint directly from them. That guarantees the paint in the bucket is the paint for which you paid.

Oh! a word of caution: the new latex waterbased tower paint is very easy to use and clean up. But water-based paint freezes and becomes a useless bucket of expensive goo. So do not store it in an unheated tower shack and wait till next spring.

By following the suggestions above, you should get a long-lasting paint job at a reasonable price, keeping you in compliance with the painting requirements in your station license.

Or, you could wake up one morning with Pink Tower Syndrome!

– – –

Ed Trombley is an ace Field Engineer at MunnReese, Inc. in Coldwater, MI, You can contact Ed at ETrombley@Munn-Reese.com